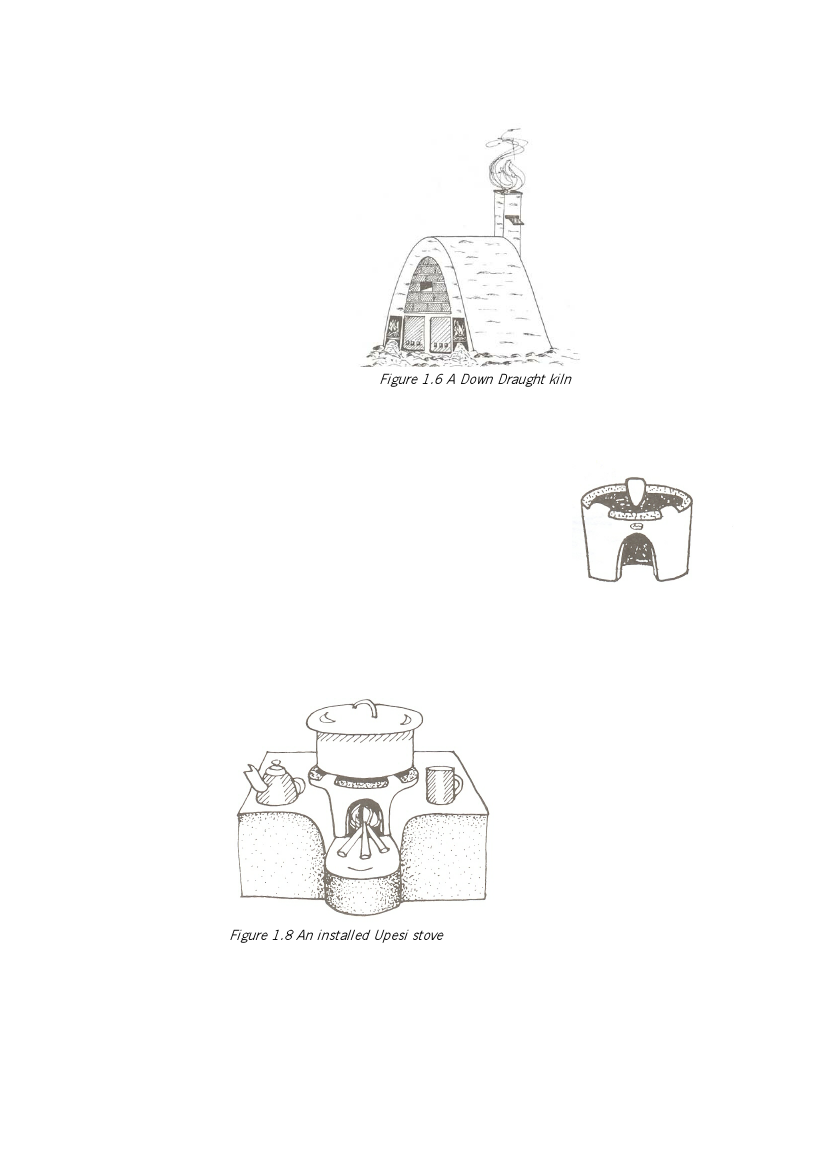

Figure 1.6 A Down Draught kiln

Why design a new kiln?

In 1989, IT started to train groups of women potters in West Kenya to produce and market an improved

cooking stove. The stove, known as Upesi or Maendeleo, is designed to burn

wood and agricultural waste such as maize cobs and stalks. The improved

cooking stove uses less fuel than the traditional three-stone fire. It produces

less smoke and is safer for both the cooks and their children.

The stove 'liner' is made from fired clay. When the pottery groups first learnt to

make the stoves, they fired the liners in Figure 1.7 An Upesi liner their

traditional bonfires or pits. The potters were often unable to fire their products

during the rainy season. As with their pots, quite a high number of stove liners cracked during firing,

sometimes as much as 40 per cent or even higher due to the rapid and uneven heating and cooling processes.

The liners have thicker walls than the traditional pots, so they need to be fired for a longer period than pots.

Experience of firing Upesi liners in Kenya has shown that if temperatures of 600°C to 700°C are reached and

held for two to three hours, the liners will be adequately fired. This is difficult to achieve with a traditional

bonfire.

Figure 1.8 An installed Upesi stove

In September 1992, ITDG's Stove and Household Energy Programme in Kenya began a one-year Kiln Project

to research on alternative simple and affordable methods of firing pottery products. The idea was to develop

an intermediate kiln.

The design criteria were to ensure that the new kiln was:

• made using local materials, in this case local bricks

5